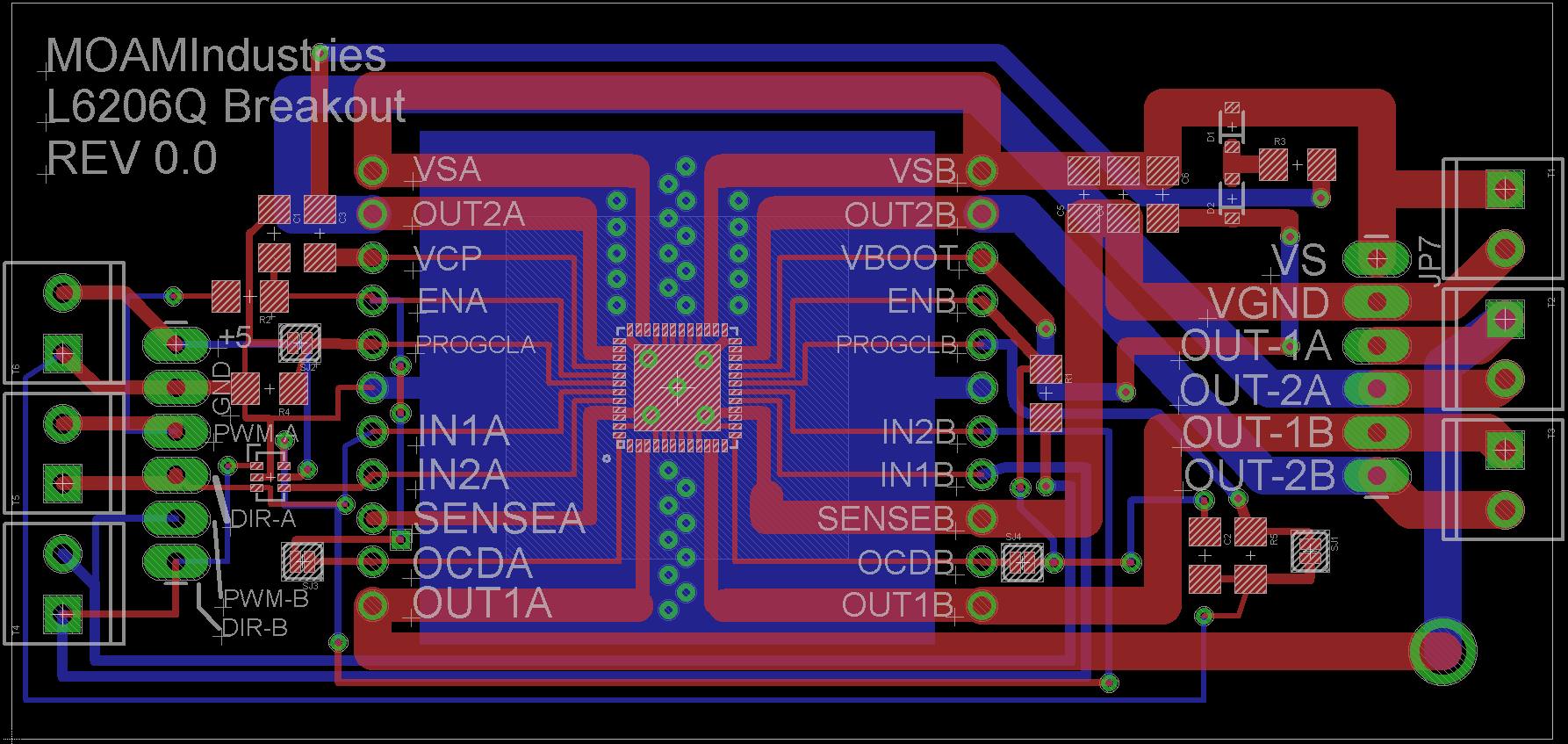

The recipe of the day here at MOAM is to work on a motor controller breakout, a test bed for another project. The module is an L6206Q which is a dual 2 amp per channel motor controller with current limiting and thermal cut out. They are a very flexible motor controller and one we are interested in working with in other projects.

So several weeks ago we developed a small testing PCB and had them made through Seeed studios fusion PCB service. Now it is not really cost effective or terribly easy to get solder stencils made (are you listening seeed!) through another manufacturer although i belive there are some prototyping services that offer a stencil with their pcbs, they are just a little too expensive for our liking at the moment. So we somehow need to solder a VQFN package with a 0.3mm pitch. Our tools are a $25 toaster oven, our reflow controller prototype and a mediocre Atten soldering station and we are hopefully going to follow this very informative guide we have found online

Now unfortunatly we dont have any hot air reworking tools (they are on a very extensive list) neither do we have a warming plate so the first step of the day is to go and buy and electric skillet and build some extra functionality into our reflow firmware to help it function as a warming plate, fingers crossed!