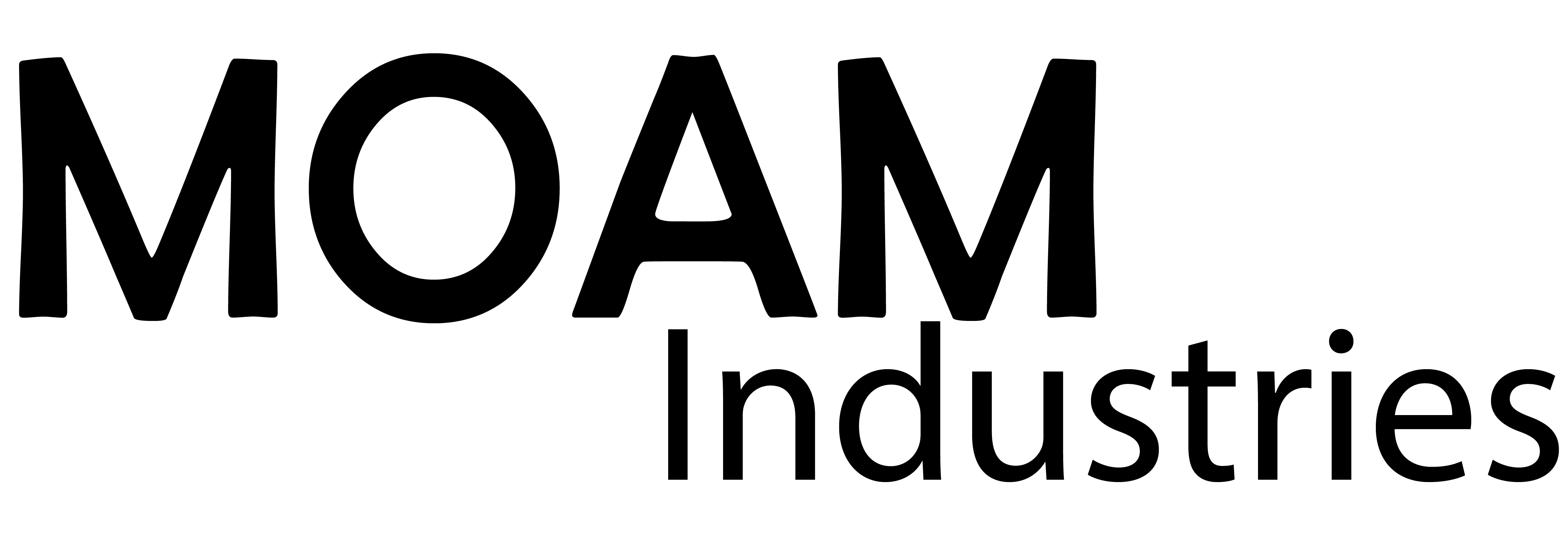

Happy days, the existing shaft was located within several mm of center making the task of machining and installing the taper lock bushes relatively straight forward. Once mounted on the lathe and dialed in to run true the center was bored out to 75mm and both ends were faced (partially).

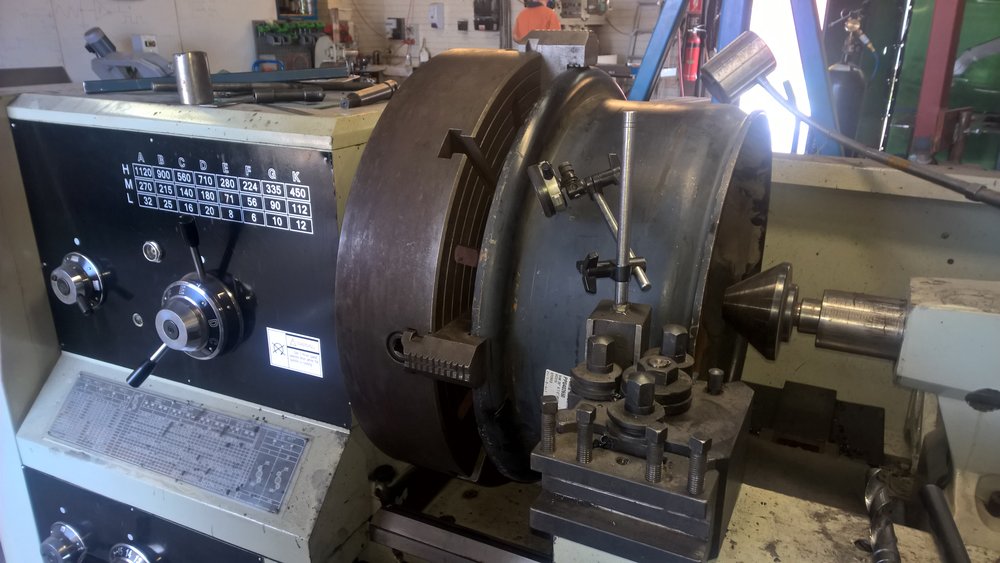

To save clocking up the rim for a second time to machine the other face a modified boring tool was used with a piece of tool steel. This allowed a small portion of the face to be cleaned up so the weld on hub could be seated flat and square with the other face. Two 8mm keyways were cut into a 700mm long piece of 30mm dia. shaft. This was used to align both taper lock hubs on both rotational planes. Once fastened the hubs were tacked and then welded into place.

Could probably use a protective coat of paint at this stage….. Next step is a rough frame to start working with the motor & brakes.